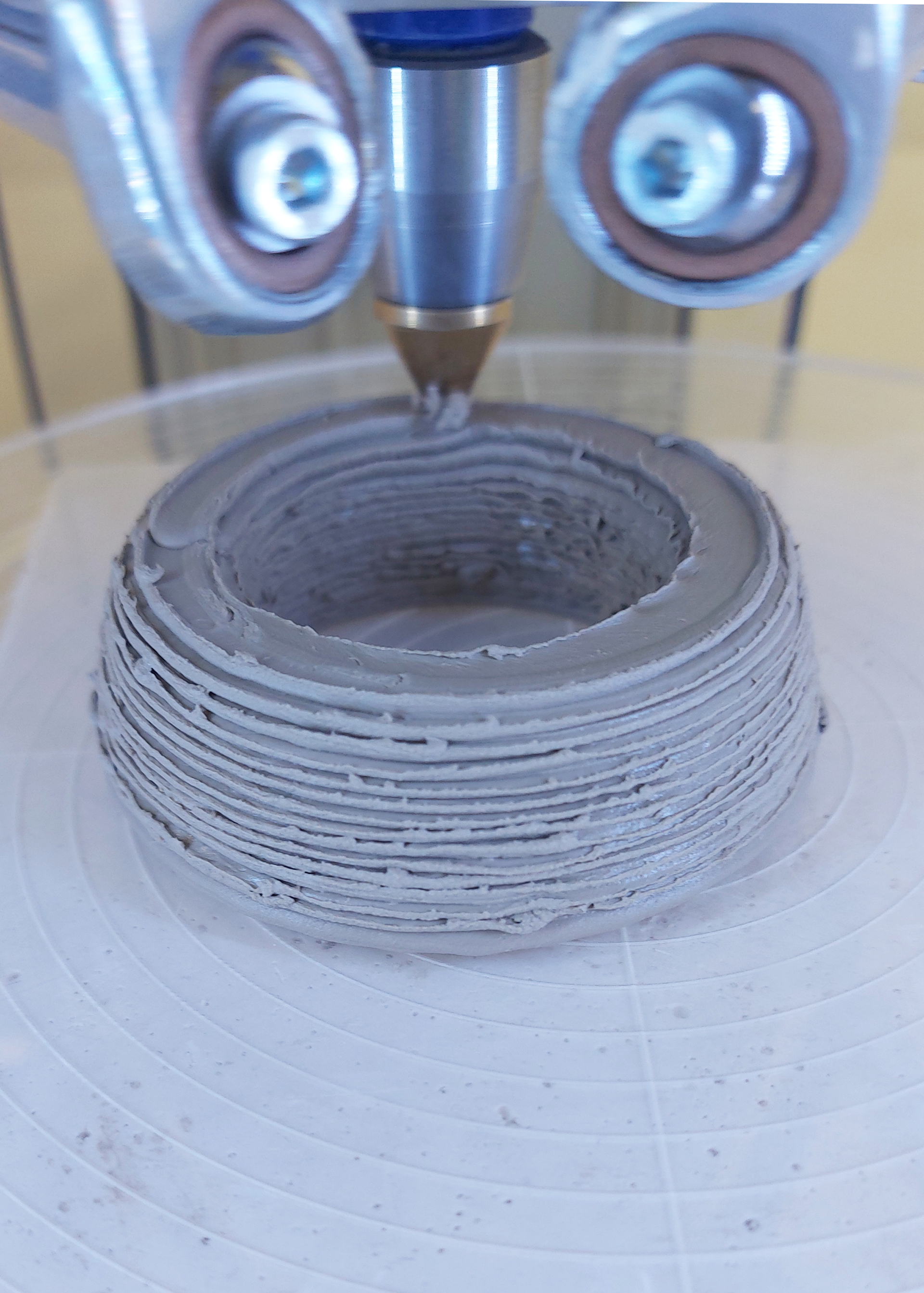

Within the workshop times we were challenged to use the ceramic 3D printer and experiment with the flow and speed of the clay. The printer isn't always predictable so making sure that we experimented with it meant that we were able to know how to work the printer in the future.

I first started using the printer to print out a simple cylinder. I controlled the flow throughout the printing to ensure that the clay didn't 'splodge' and start dragging along the clay. The last part of the printing started to get thicker and made this curved top. I then did it again with the flow adjusted to 10 and the speed 100 and the cylinder came out neat and straight with no curved parts.

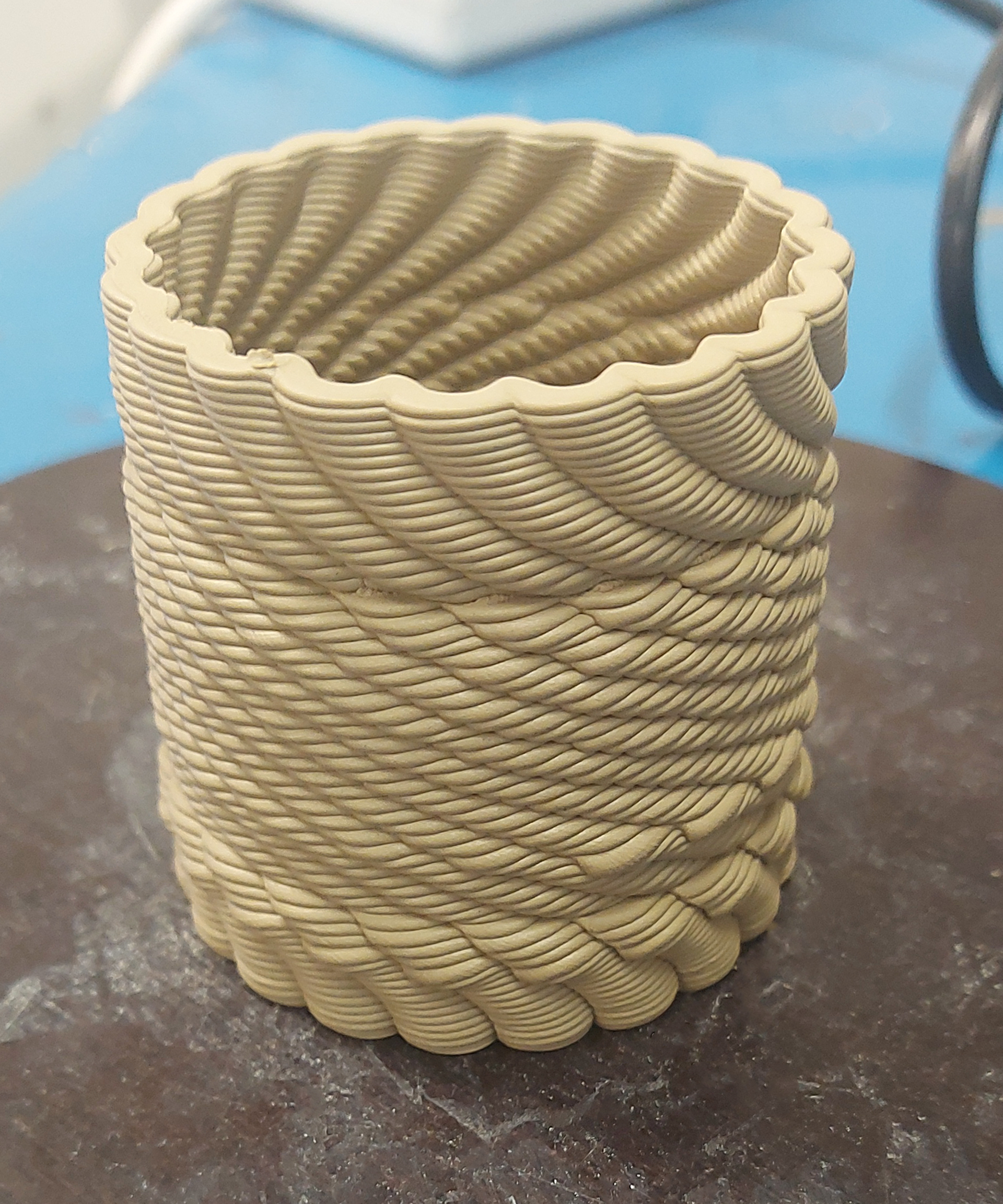

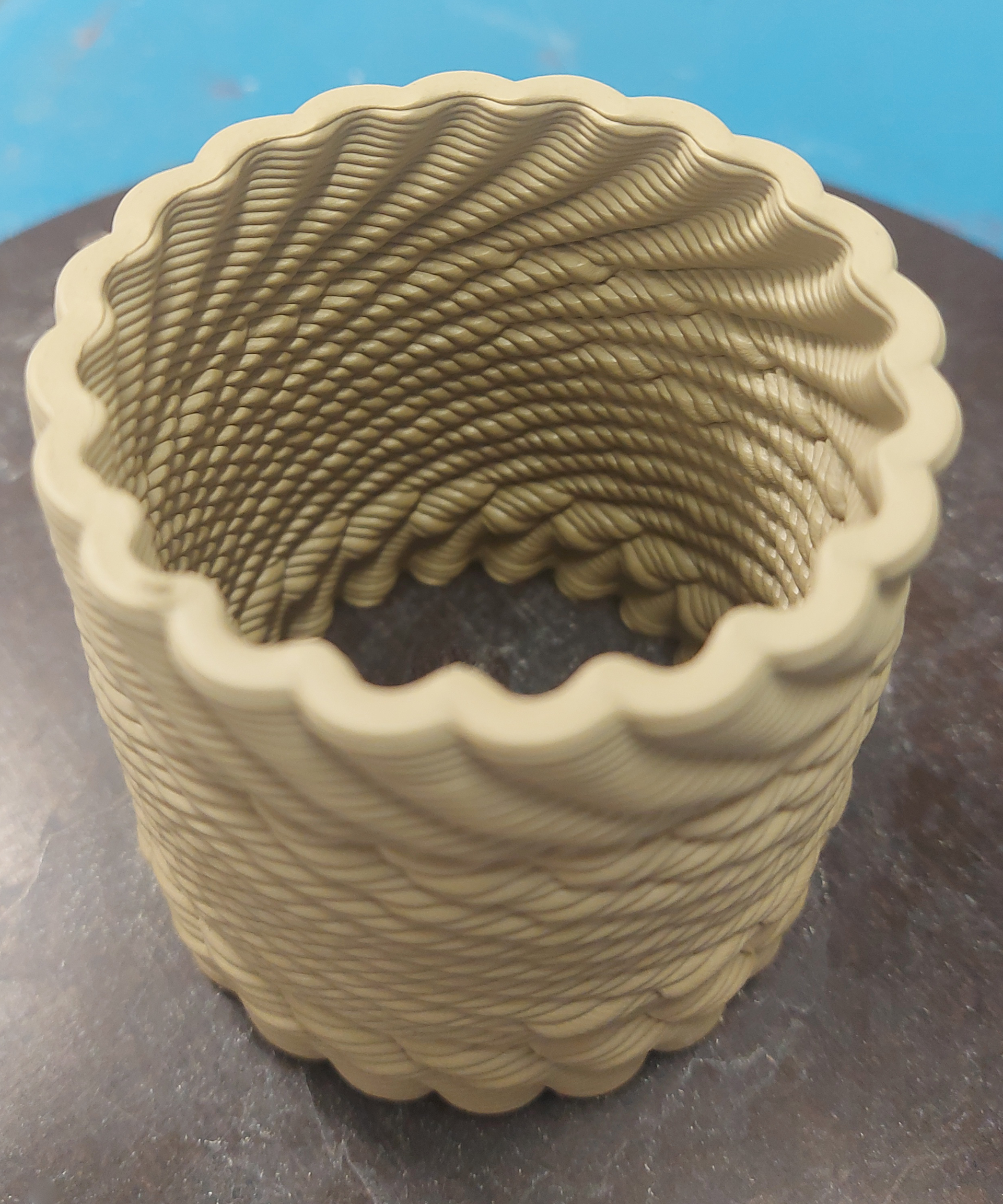

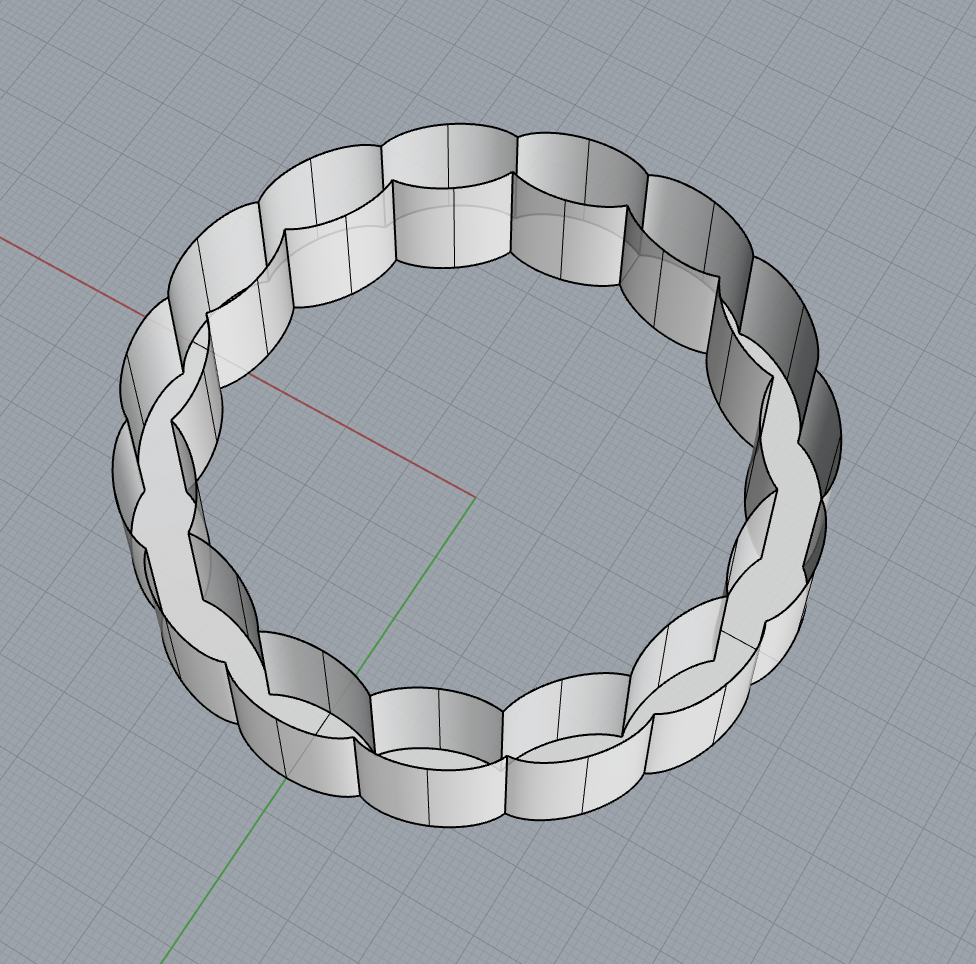

I also experimented with different flows on the twisted cylinder, making different patterns by adjusting the flow. The speed was kept at 80 and then I adjusted the flow at different values throughout the piece. I started with a flow of 10, then I changed it to 40, then back to 10, 20, 40 and then finished with a flow of 10. I thought that the different flows made the twists more interesting and created and interesting pattern throughout the piece.

Below are the glazed ceramic pieces with a clear glaze.

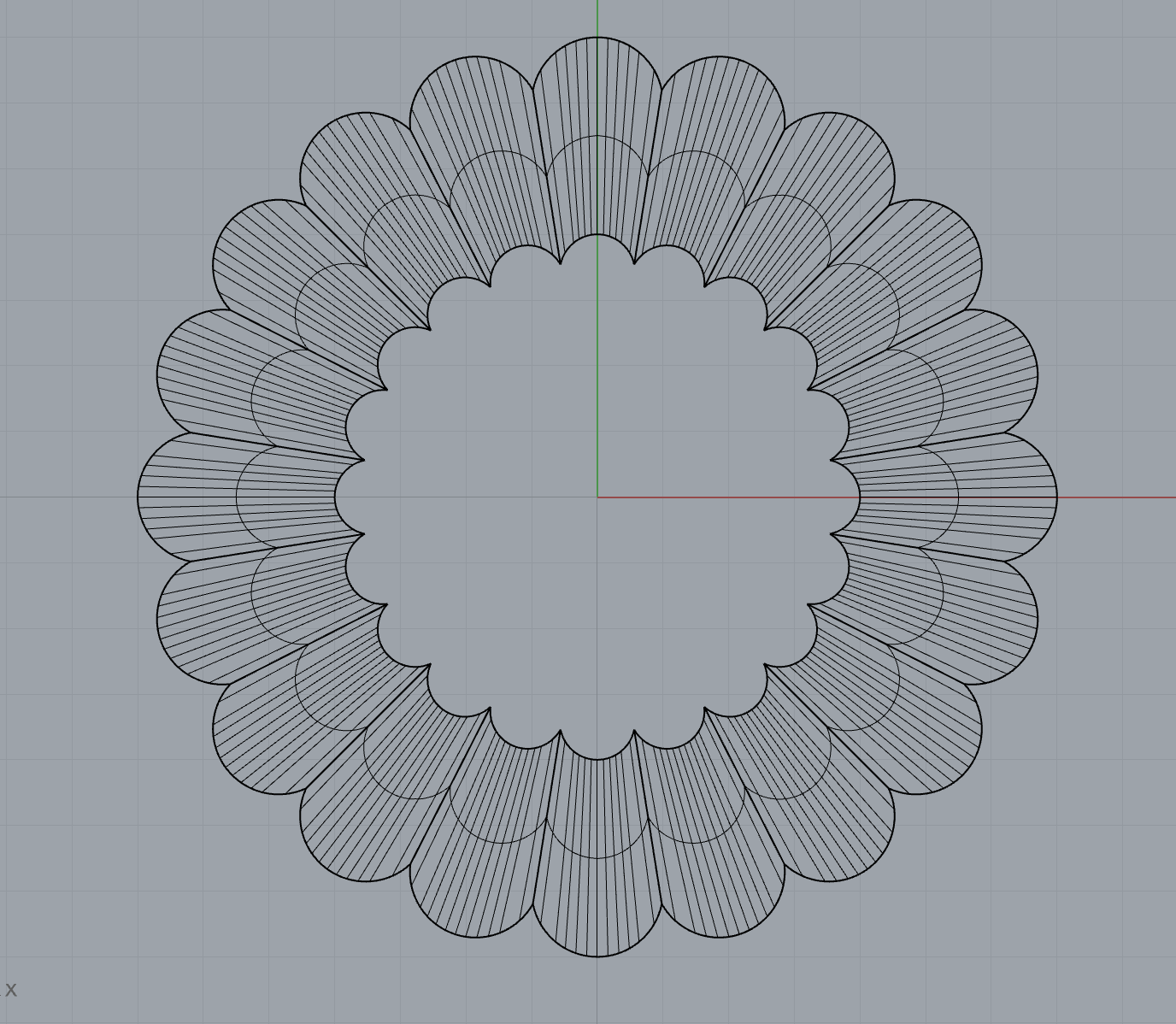

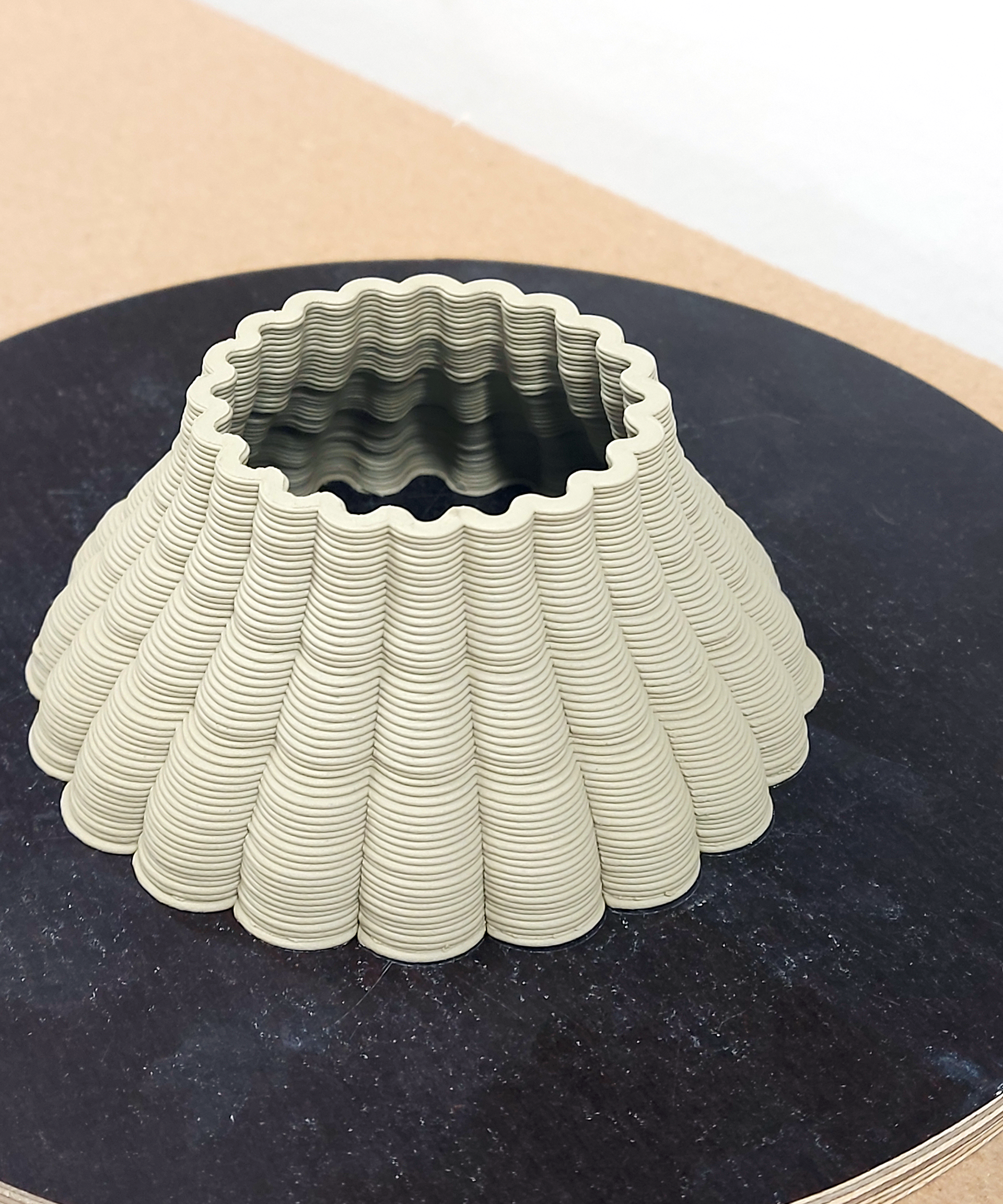

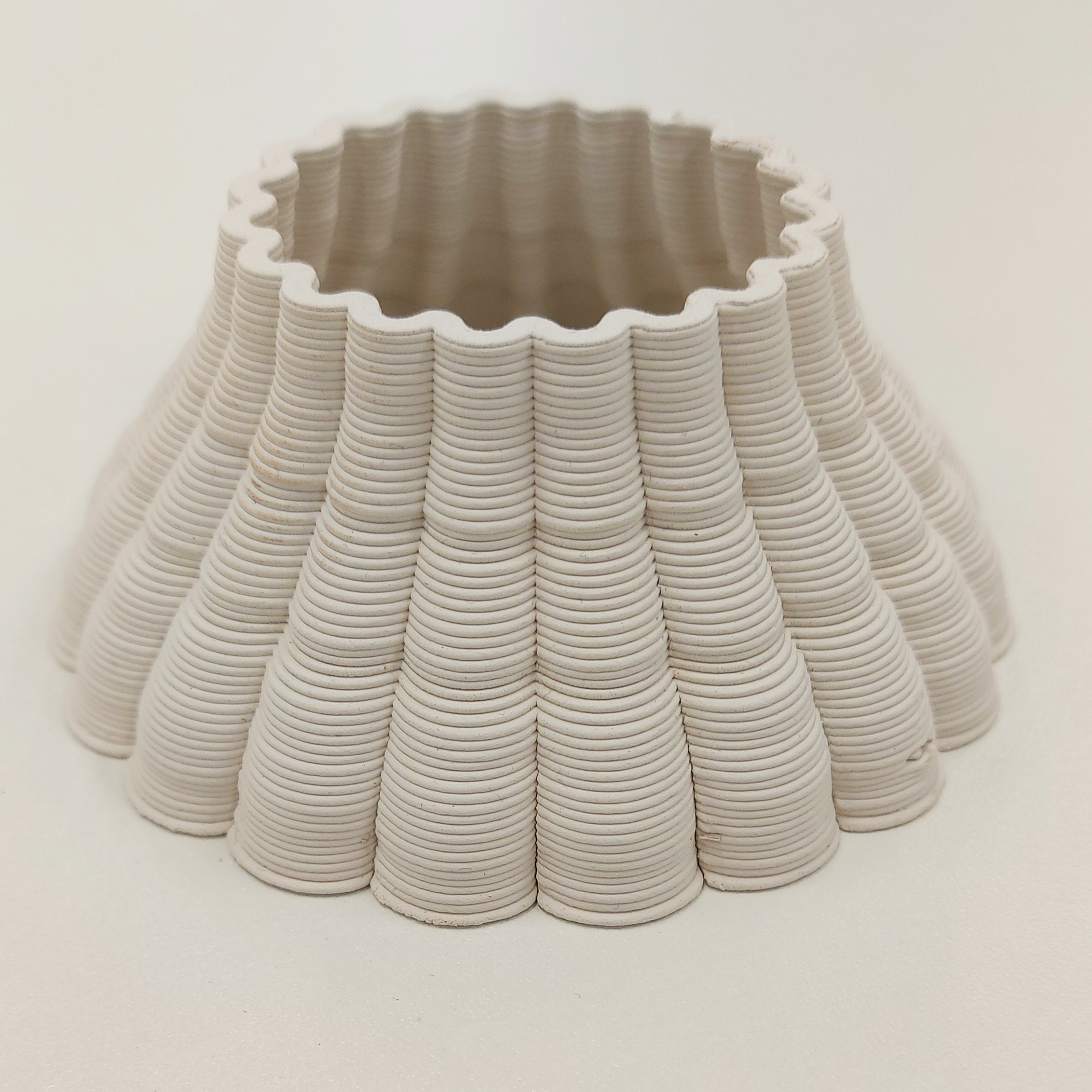

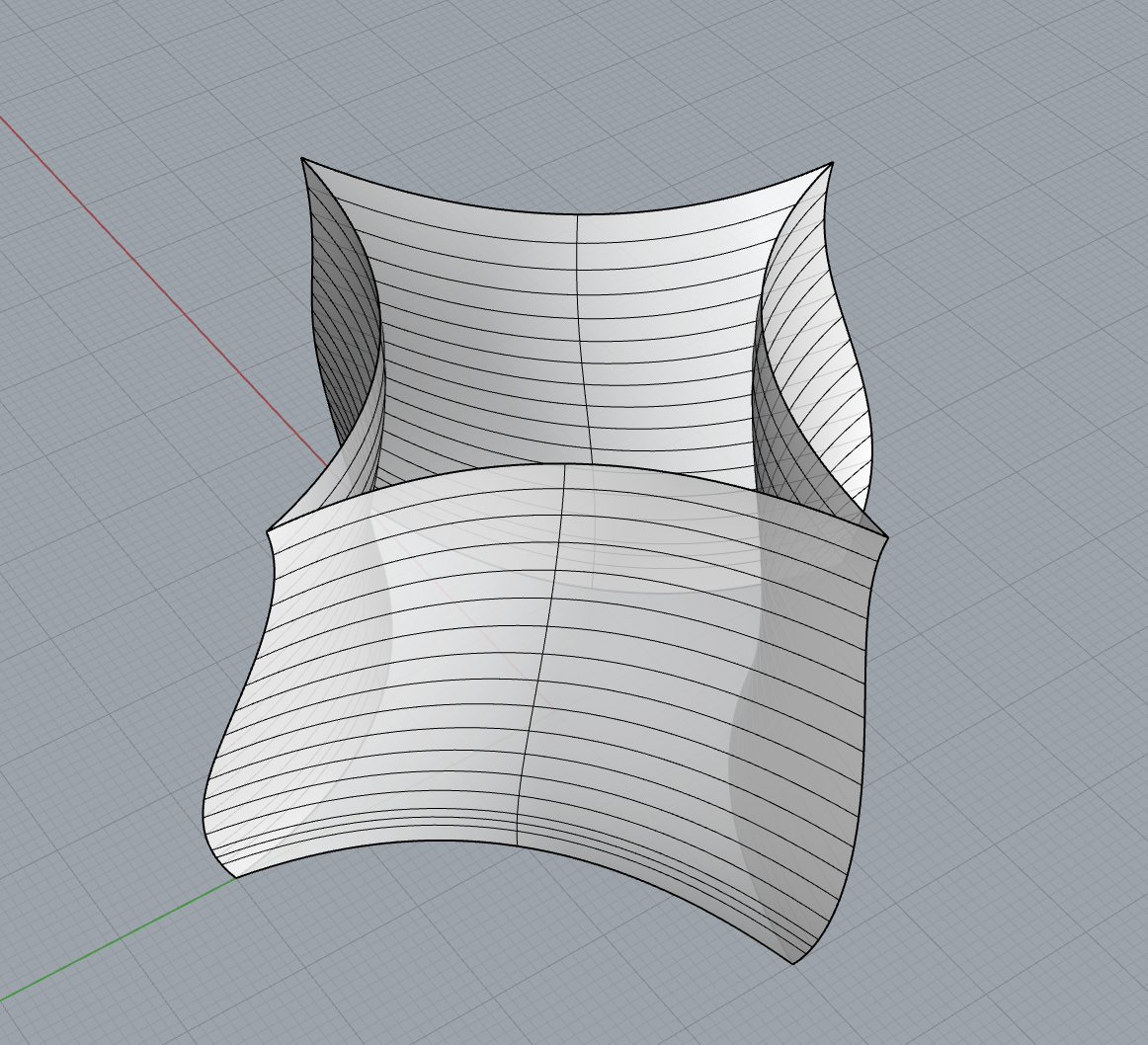

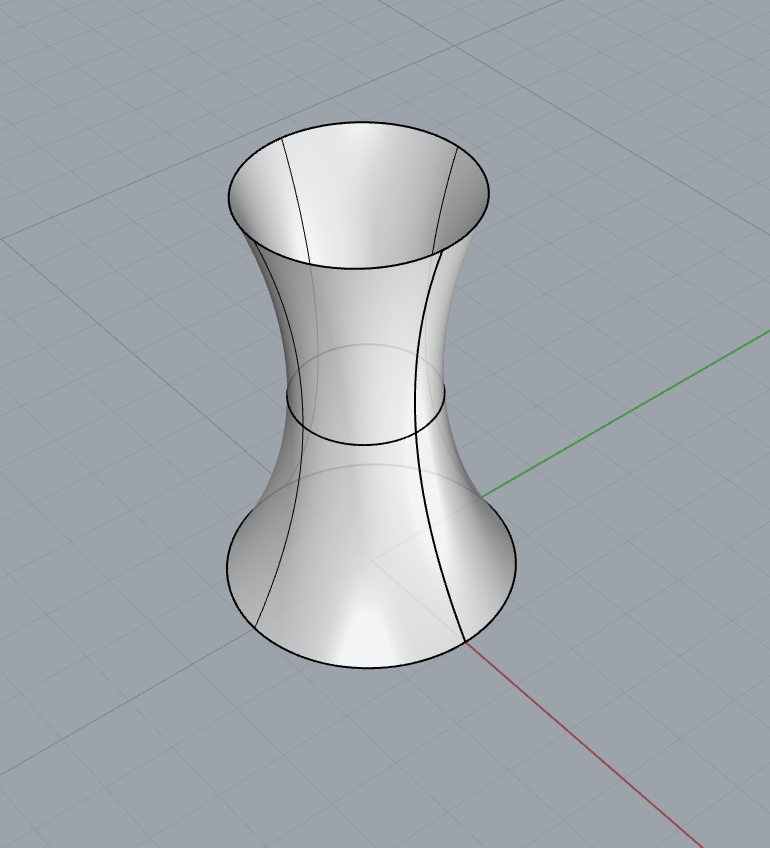

I then went on to create a new shape using Rhino which was a curved form that curved out and had a frilled edge. I used the loft function and the Array Polar function which repeated a circle shape along a curve. I really like using 3D modelling and this is a technique I want to use within my project.

I then started to print it on the 3D ceramic printer. The first few tries did not work with the clay not flowing out of the printer properly due to a decrease in pressure so once this was sorted, I then printed the form. I used a hairdryer to make sure the form was able to hold the clay and it didn't sink. This ended up with the clay printing the shape seamlessly and the form holding.

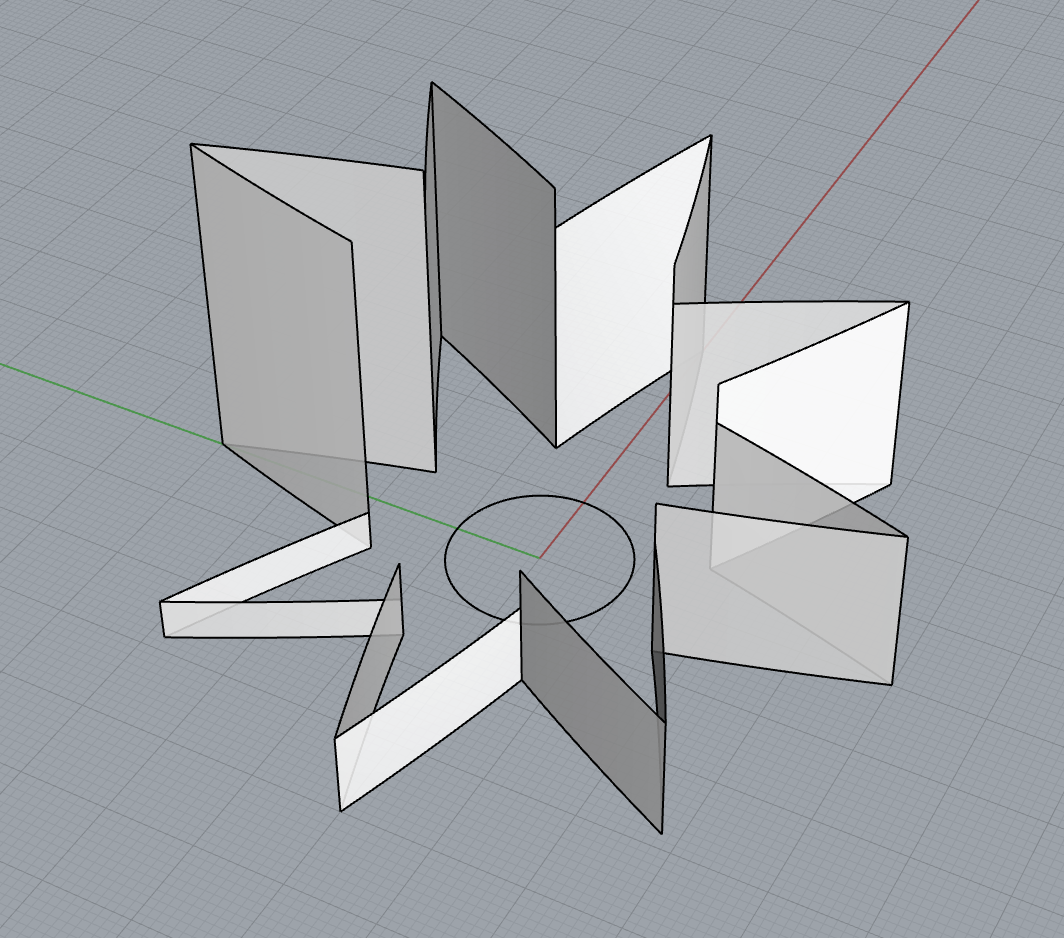

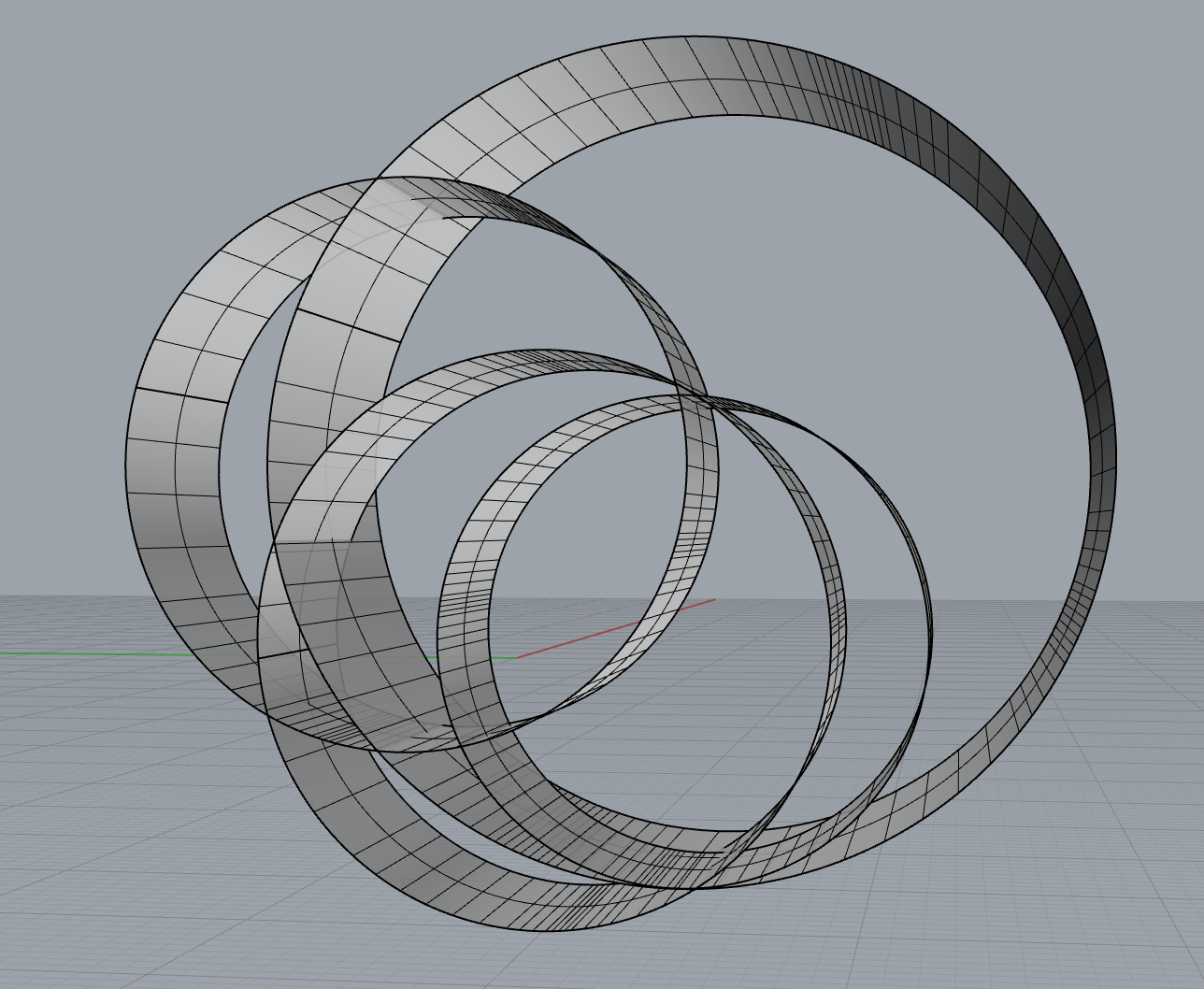

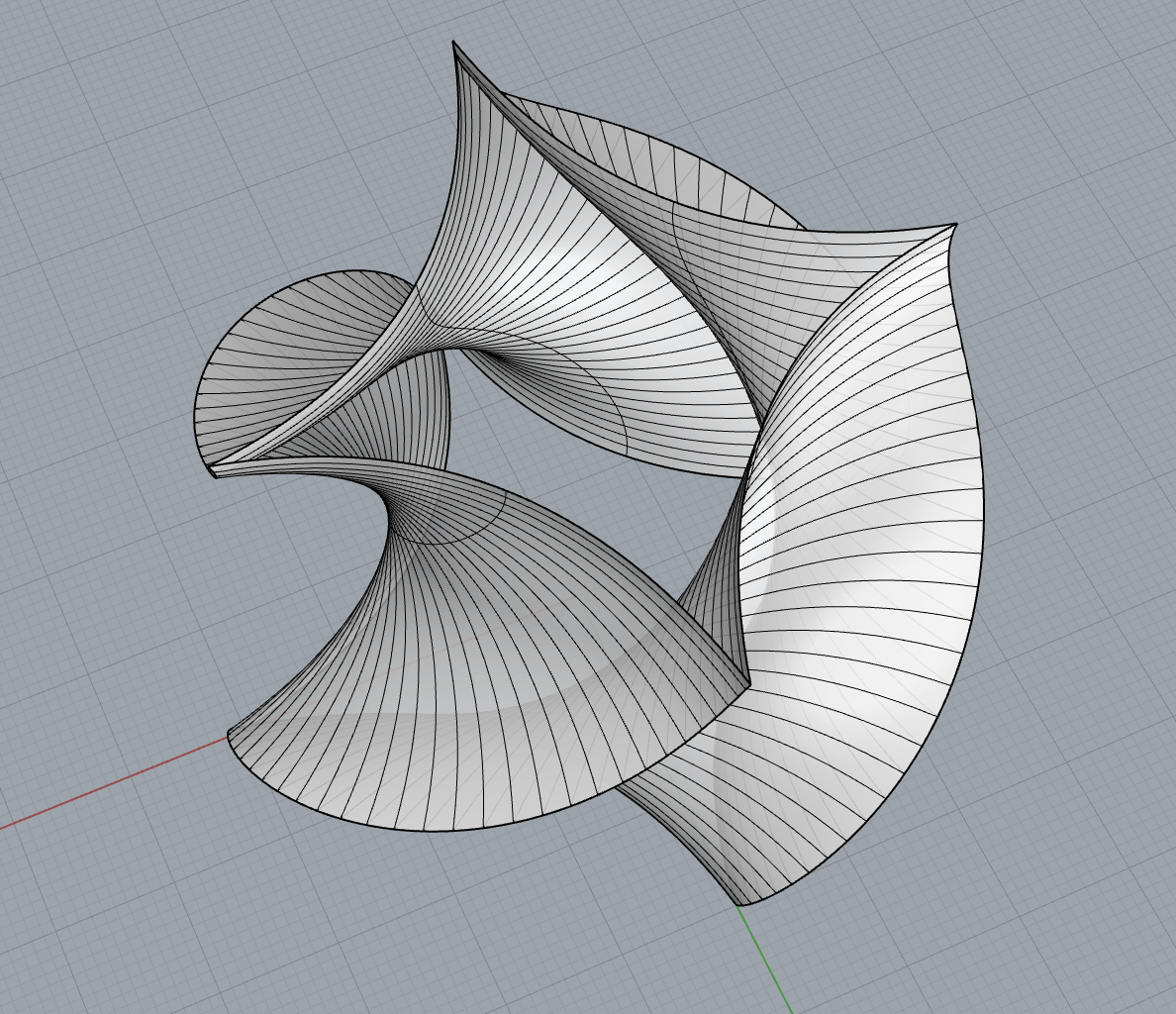

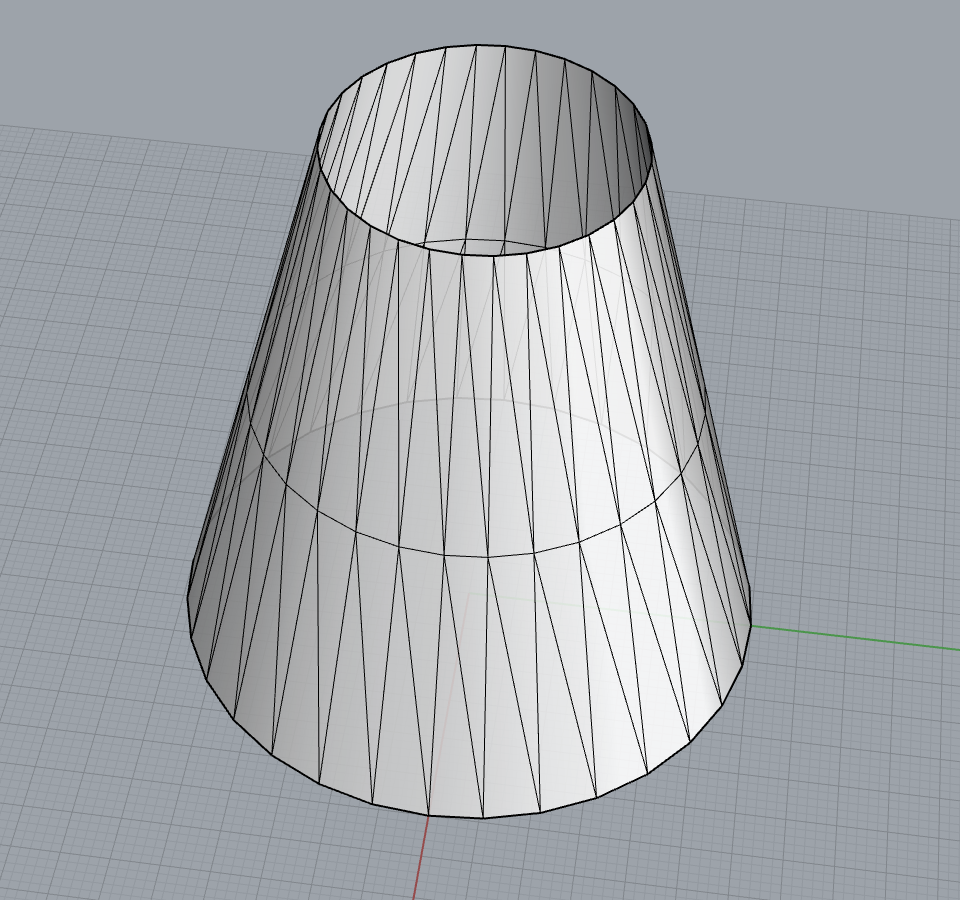

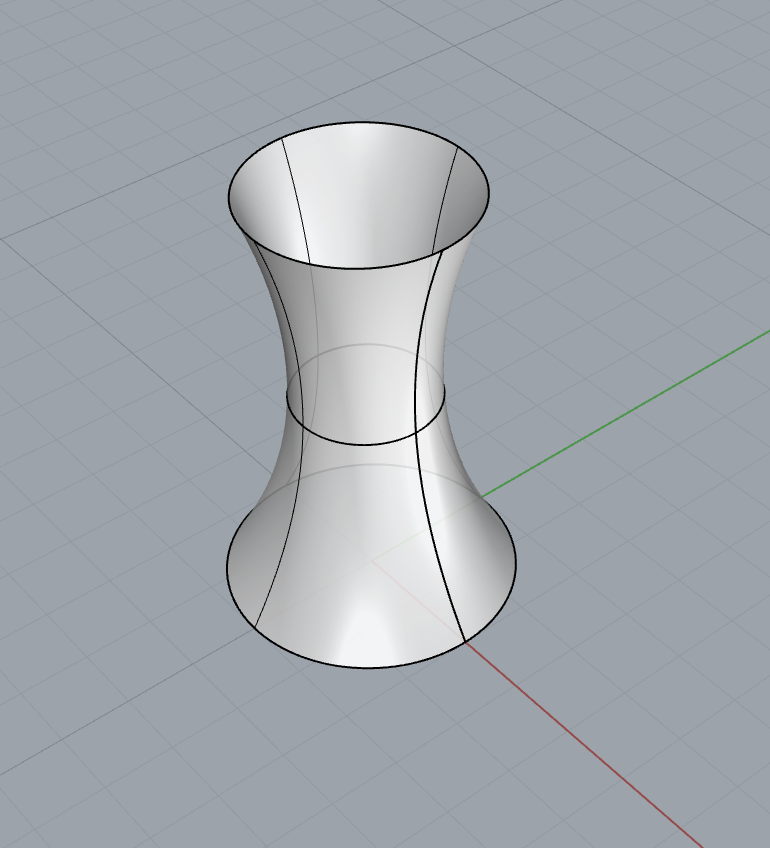

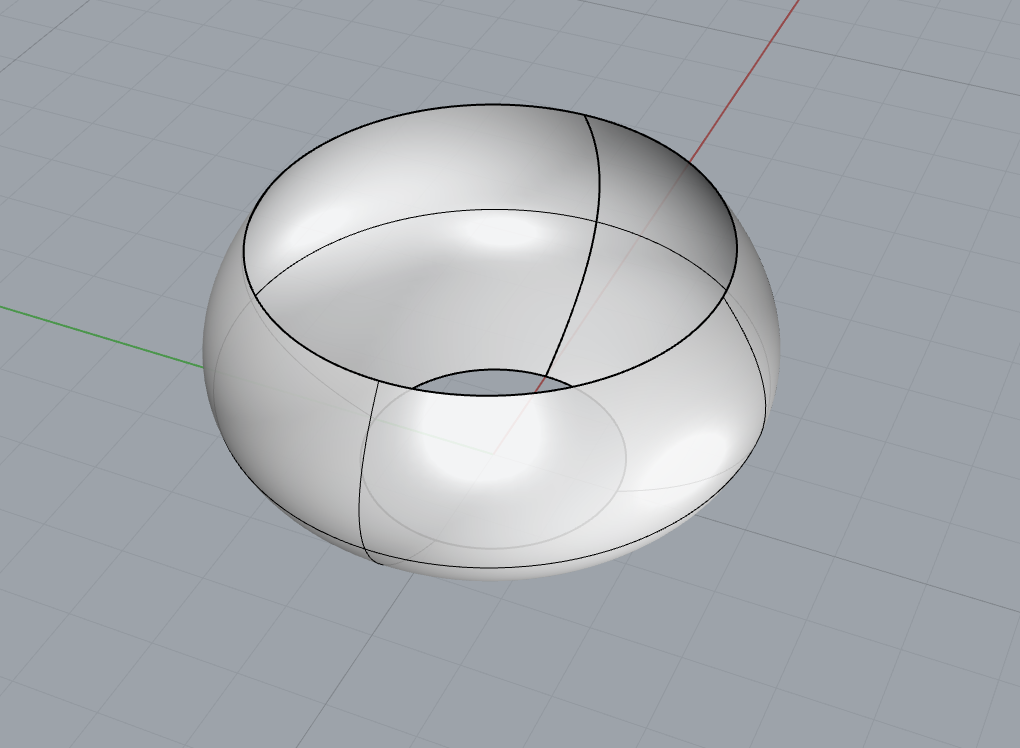

I also experimented with Rhino and looked at the different shapes that I could make using the software. From different functions to how far I could twist some shapes, below are screenshots of these experiments.

I really liked the twisted diamond shape that I made (4th picture above) and wanted to see how it would look printed. My first attempt went wrong halfway through but on the second try the piece came out quite well but in my opinion wasn't as smooth as I wanted it to be. Unfortunately I lost this piece and was unable to get a photo of it.

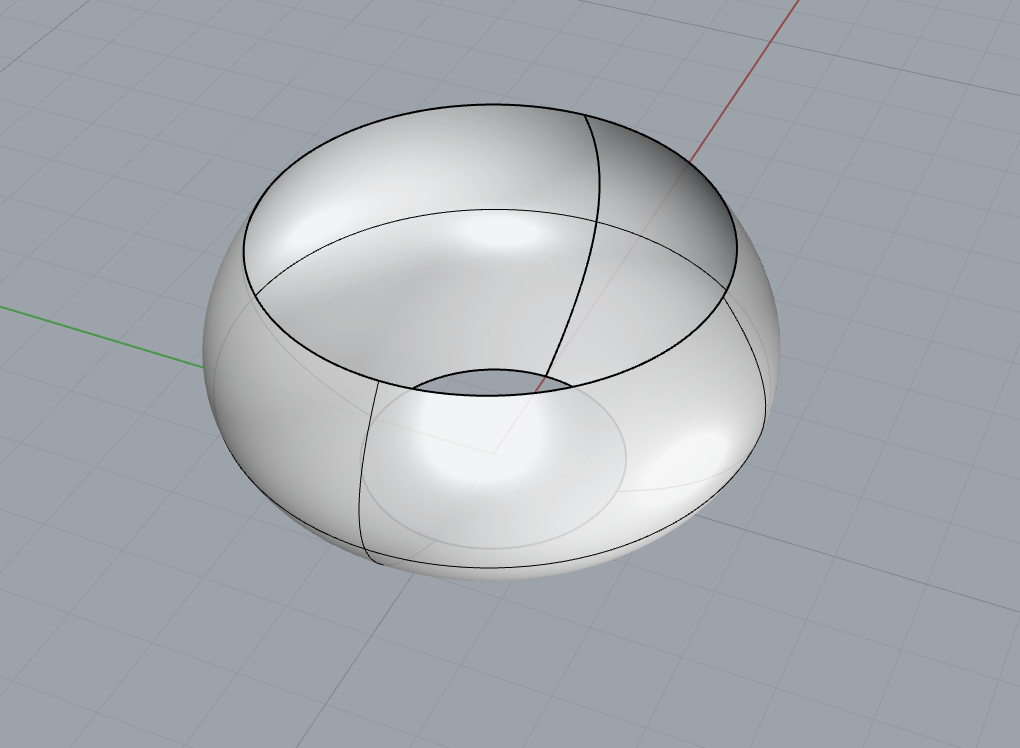

I then used Rhino to create some small pieces inspired by Ancient Greek ceramics. Some drinking vessels have a large stem at the bottom so I wanted to use this as inspiration for small cups. I created a rounded cup which I thought was more modern and combined it with a cone at the bottom.

When printing the piece, the clay was coming out quite thick and so I decided to amend the piece by making the base of the cone thinner and then making it taper in and back out to fit the cup on top of the cone so it's less of a cone shape and more curved.

These were two outcomes from things going wrong when printing due to the nozzle being too high or there being an air bubble in the tube of the printer. I thought that the spiral pattern could potentially be used as a decoration on top of clay.

I was inspired by an Ancient Greek kylix to create this form. I created a rounded circular cup with a curved cone like shape that the cup would stand on. This is like a kylix where the bowl would sit on the stand and be used for drinking wine.

I fired both the bottom cone and the top cup of the piece without realising that I would need to attach both of them first so I had to print them again. But with this I also realised that the pieces would need to be flattened a bit due to a small bump so this was something I looked for when I printed the two pieces again.

Putting together these pieces was really difficult as I had to make sure that my hatching was very light but deep enough to make sure that the slip could attach the pieces properly. I tried to be very careful as the pieces were quite delicate and light but when I attached the two pieces it snapped and I decided to create two small cups with the pieces instead, using two small discs of clay to create bases for the cups. I then glazed the two pieces in a honey glaze because although it's quite thick I wanted to see glazing that was different to the glazes I had used already for other ceramic pieces.

Overall, I enjoyed creating pieces using the ceramic printer and was able to apply the skills I learnt in Rhino to my project. However, I found the preparation and the actual use of the machine quite challenging. The machine itself seemed to break a lot and I feel like this affected my experience using the machine and made me not want to use it as much. I would like to use the machine in future projects but I would have to do it with other people so that we can work together to overcome any challenges we might face.

Links to ceramic printing I found during my research:

https://www.designboom.com/project/kruiskop/

https://www.dezeen.com/2018/10/18/studio-joachim-morineau-dripping-machine-ceramic-design/